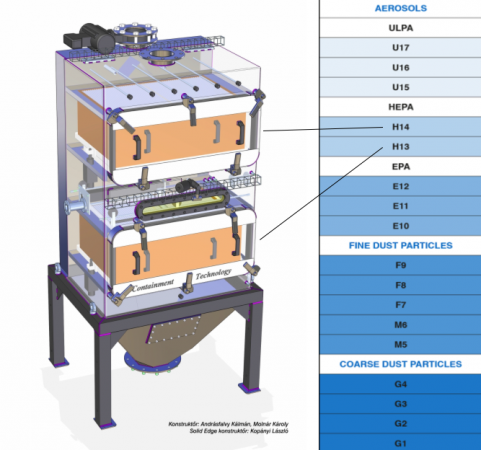

HEPA filter cassettes for the filtration of dust-laden process air in self-cleaning HEPA filter units.

The original manufactured since the 1970ies

by the inventor of the self-cleaning HEPA filter system in 2nd generation

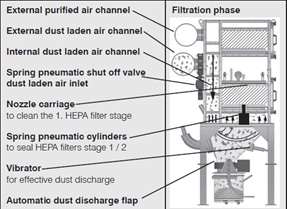

Function of self-cleaning HEPA filter systems

Technical features HEPA filter cassettes

Safety HEPA Filter Cassette Stage 2

- Constant filter efficiency H 14 EN 1822

- Max. pressure differential > 2 kPa.

- Grounded incl. ground monitoring

- Combustible with MDF frame

- With serial number and certificates

Self-cleaning HEPA Filter Cassette Stage 1

- Filtration efficiency F9 / H13

- Max. pressure differential > 3.5 kPa.

- Max. dust laden air level 150 g / m³

- High dust holding capacity

- Grounded with ground monitoring

- Combustible with MDF frame

- With serial number and certificates

Filter media efficiency and seal test

During the validation process, as well as during operation and after each filter change, the security filter stage 2 can be tested by installed measuring lances and a laser particle counter to proof that the efficiency value of H14 / EN1822 has been reached. The sealing of the cassette is also checked here.

The result of the testing is documented and printed by the laser particle counter to proof the actual reached filter efficiency.

Closing the gap in containment, even when changing HEPA filter cassettes.

OEB 1 – 4

Ergonomic, easy and contamination-free filter change stage 1 and 2. with filter lifting table and double bag in bag out method and sealing tool.- The HEPA filter cassette can be sealed in its plastic bag, whereby the filter unit remains accordingly sealed. Without contamination of the operator the cassette can be transported to incineration within its sealed bag.

OEB 5 – 6

Ergonomic, easy and contamination-free filter change stage 1 and 2. With filter lifting table and double bag in bag out method and sealing tool.- For additional security the sealed HEPA filter cassette in its plastic bag can be additionally sealed in a fibre drum and transported to incineration.

Explosion prevention by grounding control of HEPA filter cassettes

High safety standard by earthing monitoring

Each HEPA filter cassette is connected to the ground monitoring system of the filter unit within the control box. This ensures that the HEPA filter cassettes cannot be statically charged if there is no ground connection and that no ignition spark can occur, which could cause a dust explosion.

If one or more cassettes are not connected to ground, there is an error displayed at the touch panel.

Furthermore, the proper function of the filter unit as well as all possible errors and the standstill of the filter system is displayed simultaneously in each production room by green, yellow and red signal lamps.

HEPA filter cassette / unit types

| Dimensions mm |

Total filter area m2 |

HEPA cassette

type |

Unit type |

OEB level |

||

|---|---|---|---|---|---|---|

| 305 x 610 x 292 | 10 10 |

HF1/10G HF2/10G |

|

MMS 10/3.2 GB |  |

5 – 6 |

| 610 x 610 x 292 | 20 20 |

HF1/20G HF2/20G |

|

MMS 20/3.2 GB |  |

4 – 5 |

| 762 x 610 x 292 | 24 24 |

HF1/24G HF2/24G |

|

MMS 24/4.2 |  |

2 – 3 |

| 915 x 610 x 292 | 28 28 |

HF1/28G HF2/28G |

|

MMS 28/3.2 |  |

1 – 2 |

Technical Data HEPA Filter-Cassettes

Active, self-cleaning HEPA filter cassettes stage 1

Standard: Class F9 – H13

PTFE coated filter media: Class H13 certified according to EN 1822

Leakage and grounding test with certificate of manufacturer

| Air volume m3/h |

Type | Dimensions mm |

Filter area m2 |

Spec. filter area load m3/m2h |

Initial pressure loss Pascal |

Final

pressure loss

Pascal |

Temp. max C |

Max. load

dust laden air g/m3 |

|---|---|---|---|---|---|---|---|---|

| 750 | HF1 / 10 G | 305 x 610 x 292 | 10 | 75 | 150 | 3.500 | 100 | 150 |

| 1.500 | HF1 / 20 G | 610 x 610 x 292 | 20 | 75 | 150 | 3.500 | 100 | 150 |

| 1.800 | HF1 / 24 G | 762 x 610 x 292 | 24 | 75 | 150 | 3.500 | 100 | 150 |

| 2.100 | HF1 / 28 G | 915 x 610 x 292 | 28 | 75 | 150 | 3.500 | 100 | 150 |

| 1.000 | HF1 / 10 G PTFE | 305 x 610 x 292 | 10 | 100 | 170 | 3.500 | 100 | 150 |

| 2.000 | HF1 / 20 G PTFE | 610 x 610 x 292 | 20 | 100 | 170 | 3.500 | 100 | 150 |

| 2.400 | HF1 / 24 G PTFE | 762 x 610 x 292 | 24 | 100 | 170 | 3.500 | 100 | 150 |

| 2.800 | HF1 / 28 G PTFE | 915 x 610 x 292 | 28 | 100 | 170 | 3.500 | 100 | 150 |

Passive Safety HEPA filter cassettes stage 2

Class H14 certified according to EN 1822

Leakage and grounding test with certificate of manufacturer.

| Air volume m3/h |

Type | Dimensions mm |

Filter area m2 |

Spec. filter area load m3/m2h |

Initial pressure loss Pascal |

Final

pressure loss

Pascal |

Temp. max C |

|

|---|---|---|---|---|---|---|---|---|

| 750 | HF2 / 10 G | 305 x 610 x 292 | 10 | 75 | 150 | 2.000 | 100 | |

| 1.500 | HF2 / 20 G | 610 x 610 x 292 | 20 | 75 | 150 | 2.000 | 100 | |

| 1.800 | HF2 / 24 G | 762 x 610 x 292 | 24 | 75 | 150 | 2.000 | 100 | |

| 2.100 | HF2 / 28 G | 915 x 610 x 292 | 28 | 75 | 150 | 2.000 | 100 | |

| 1.500 | HF2 / 10 MP | 305 x 610 x 292 | 21 | 71 | 320 | 2.000 | 100 | |

| 3.000 | HF2 / 20 MP | 610 x 610 x 292 | 42 | 71 | 320 | 2.000 | 100 | |

| 3.700 | HF2 / 24 MP | 762 x 610 x 292 | 49 | 75 | 320 | 2.000 | 100 | |